Tempered Glass is produced by heating the glass to a temperature range of 620°C to 700°C, followed by rapid cooling using jets of cold air. This process creates compressive stress on the surface, making the glass up to 4-5 times stronger than untreated glass.

In the event of breakage, tempered glass shatters into small, blunt pieces, minimising the risk of injury. It is commonly used in applications requiring enhanced strength and safety.

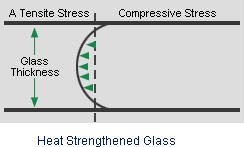

Heat-Strengthened Glass, also known as Half Tempered Glass, is heated to a lower temperature range of 600°C to 620°C and subjected to a slower cooling process.

As a result, it is approximately twice as strong as untreated glass but not as strong as tempered glass. While it provides increased strength is needed but safety glazing is not a requirement.

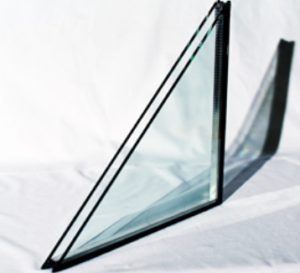

Tempered glass is a type of safety glass that has been heat-treated to improve its strength and durability. It undergoes a special thermal treatment, where the glass is heated to a high temperature (620°C to 700°C) and then rapidly cooled using jets of cold air. This process increases the glass’s strength by putting the outer surfaces into compression and the inner surfaces into tension, making it 4-5 times stronger than regular glass.

The result is a material that is not only stronger but also safer: if broken, tempered glass shatters into small, cubical fragments, reducing the risk of serious injury. This makes it the ideal choice for applications where both strength and safety are essential.

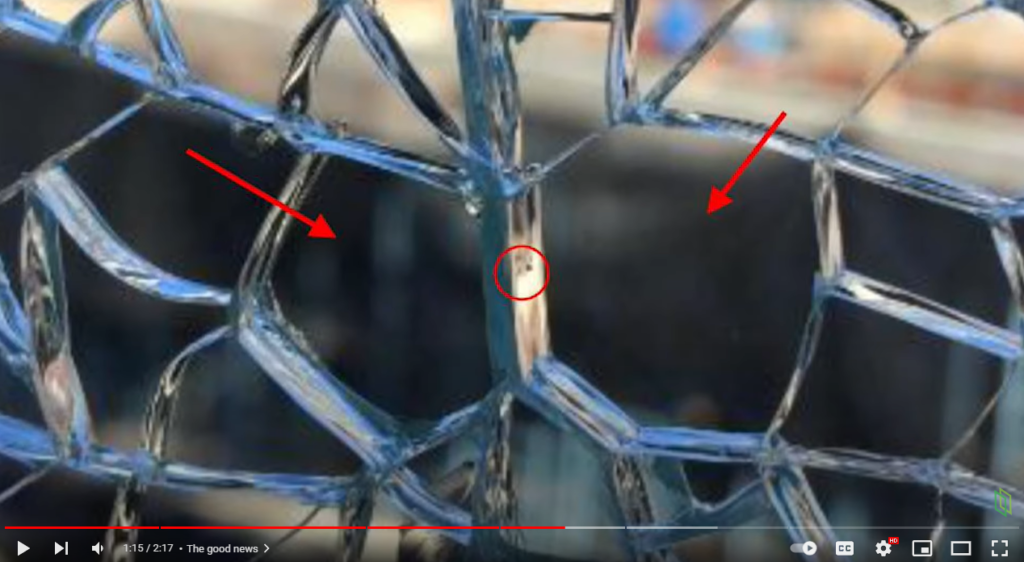

In rare instances, tempered glass may break without an apparent external cause due to internal inclusions, particularly Nickel Sulphide (NiS) stones. These inclusions can form during the glass production process due to nickel contamination.

When the glass is exposed to temperature fluctuations after installation, the NiS inclusions, which measure between 0.003 to 0.015 inches in diameter, may expand, creating internal stress that can lead to spontaneous breakage.

Although this phenomenon is extremely rare, the risk can be minimised by subjecting the tempered glass to a Heat Soak Test, which helps detect and eliminate glass with potentially hazardous inclusions.

The heat soak test is designed to minimise or eliminate the risk of spontaneous breakage in tempered glass caused by internal stone inclusions, particularly Nickel Sulphide (NiS). This process involves exposing tempered glass to elevated temperatures for a specific duration.

The heat soak process consists of three phases: heating, holding, and cooling. The primary objective of this test is to identify and break glass that may be at risk of spontaneous breakage, ensuring that any glass with NiS inclusions will fail during heat soak cycle, rather than after installation.The key principle is to achieve a “break now, not later” result.

CSG Heat Soak Tempered Glass is backed by a 10-year warranty. Terms and conditions apply.

Heat strengthened glass is a semi-toughened safety glass that has been heat-treated to boost strength and thermal resistance. Heated to around 620°C and slowly cooled, it develops lower surface compression than tempered glass. This makes it about 2x stronger than annealed glass, while still offering better breakage safety. Ideal for projects needing added durability without full tempering

While spontaneous breakage is less common in heat strengthened glass than in fully tempered glass, Nickel Sulphide (NiS inclusions can still pose a risk. These microscopic particles may expand over time due to a temperature exposure, potentially causing breakage.

Heat strengthened glass is not typically subjected to a Heat Soak Test, as its lower surface stress makes it less prone to NiS-related failure compared to tempered glass.

When the glass is exposed to temperature fluctuations after installation, the NiS inclusions, which measure between 0.003 to 0.015 inches in diameter, may expand, creating internal stress that can lead to spontaneous breakage.

Although this phenomenon is extremely rare, the risk can be minimised by subjecting the tempered glass to a Heat Soak Test, which helps detect and eliminate glass with potentially hazardous inclusions.

Our Solutions

Contact Us

Tan Yi Shin was appointed as Chief Financial Officer (CFO) of Crystal Group in 2018, bringing with her extensive experience in finance and operations. She graduated with a BA (Hons) in Accounting from the University of Portsmouth, United Kingdom in 2006.

With 18 years of experience within Crystal Group, Yi Shin began her career in various key roles, including Invoice Management, Customer Service Oversight, Operations Management, and Quality Assurance. Her exceptional performance and dedication led her to progressively more significant positions, culminating in her current role as CFO.

As CFO, Yi Shin oversees the organisation’s financial planning, analysis, risk management, and reporting. She has implemented initiatives that enhanced financial performance, including cost management strategies and an integrated reporting system. Yi Shin actively aligns financial strategies with operational goals, ensuring Crystal Group remains competitive and sustainable in the market.

Furthermore, she holds directorships in several other private limited companies within Crystal Group.

Frank Tan is the dynamic Chief Executive Officer of Crystal Group, bringing a wealth of experience and a visionary approach to the organisation. He graduated with a BA (Hons) in Economics from the University of Portsmouth, United Kingdom in 2008 and has played a pivotal role in steering the company’s strategic direction since his appointment as CEO in 2015.

Under Frank’s leadership, the Crystal Group has seen remarkable growth and innovation, transitioning from a national leader to a formidable player on the global stage. He has successfully spearheaded initiatives that have enhanced operational efficiencies and driven significant revenue growth, positioning the company to compete in international markets.

A key component of Frank’s strategic vision is the expansion of Crystal Group into various regions worldwide. By establishing a presence in multiple international markets, he is guiding the company through its transformation into a multinational corporation (MNC). This global expansion not only diversifies the company’s portfolio but also strengthens its ability to meet the evolving needs of clients and partners across different regions.

In his role, Frank oversees all aspects of the organisation, including financial planning, risk management, and operational alignment with strategic goals. He has implemented an integrated financial reporting system and innovative cost management strategies that have substantially improved the company’s financial performance. His commitment to fostering a strong financial foundation ensures that Crystal Group remains competitive and sustainable in the marketplace.

Frank is also deeply invested in nurturing a culture of collaboration and innovation within the organisation. He encourages cross-functional teams to work together, leveraging diverse perspectives to drive creativity and enhance problem-solving capabilities. This approach has positioned Crystal Group as an employer of choice, attracting top talent in the industry.

Furthermore, he holds directorships in several other private limited companies within Crystal Group.

Dato’ Seri Michael Tan Seng Huat is a pioneer in the glass industry, widely recognised for transforming Malaysia’s architectural landscape. As the founder of Crystal Group, his bold vision and relentless pursuit of excellence have propelled the company to the forefront of the industry. In 1999, he made history by being the first to introduce green glass into Malaysia, a groundbreaking innovation that redefined the construction and design sectors and positioned Malaysia prominently in the global glass market.

For over two decades, Dato’ Seri Michael has led Crystal Group on an extraordinary journey of growth, establishing the company as a powerhouse in the architectural glass industry. His visionary leadership has enabled Crystal Group to offer an unrivalled range of high-quality glass solutions, shaping the skyline of Malaysia with iconic skyscrapers and complex architectural projects.

Under his leadership, Crystal Group’s vision has transcended national borders. The company has embarked on an ambitious global expansion, establishing a strong presence in key international markets. As Crystal Group evolves into a true multinational corporation (MNC), it is setting up operations across various regions worldwide, further solidifying its standing as a global industry leader.

Furthermore, Dato’ Seri Michael holds directorships in several private limited companies within the Crystal Group, where his strategic insights continue to influence various facets of the organisation.

His success story is one of innovation, ambition, and perseverance, leaving an indelible mark on both Crystal Group and the glass industry at large. Dato’ Seri Michael Tan Seng Huat’s legacy is one of excellence, and his contributions continue to shape the future of architectural glass globally.